This is a primer guide to 1991-1993 164 (12v) timing belt tensioners. This is meant for new owners trying to decide on what type of tensioner to use. If you see anything incorrect or poorly explained, let me know and I'll change it. And a thank-you to all those whom I pirated pictures from.

>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>

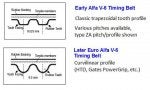

If there’s one aspect of the 164 12v V-6 engines that strikes terror into the hearts of it’s owners, it’s the timing belt. Keeping in mind that since these 164 engines were designed in the 80s and the timing belts are of the early trapezoidal design. This means the teeth on the belt form a small trapazoid. More modern belt designs are of the “curvilinear” type which forms a sort of half circle. The trapezoidal types do not have the amount of grip that that the modern curvilinear types do. That said, trapezoidal belts are just fine under most circumstances, given sufficient “belt wrap.” Belt wrap is the how much of the belt grips the pulley which it drives. A trapezoidal belt with lots of “wrap” grips the pulley well and poses no special problem.

Later Alfa V-6 engines use a curvilinear belt. As an aside, early 12v engines can be retrofitted to use the curvilinear belts, but finding the various pulleys/pieces/parts is difficult and must be sourced from Europe.

Which brings us to back to the 164 12v Busso engine. The problem with the early Busso engine is that the belt wrap on the rear camshaft pulley can reasonably be described as “just barely adequate.”

Under good circumstances, given good maintenance, non-extreme conditions, and not allowing the engine to rotate backwards, it works fine. However, given problems and the right circumstances, there is a real possibility that the belt will skip/shear teeth and go out of valve timing. Given that the engine is an “interference” type engine, if the timing slips by more than 2 teeth, it’s almost a certainty that there will be a collision between some valves and the piston. The result of this is a very expensive repair and very often has led to the car being junked as non-economical to repair. And virtually all of this is unnecessary and preventable.

Causes of 12v Timing Belt Failures

The VAST majority of timing belt failures can be attributed to three causes:

1. Failure to adhere to Alfa recommended change intervals.

2. Failure of the temperature sensitive tensioner spring of the mechanical type tensioner. This can either be by simple material failure or by installation error with the installer inadvertently breaking it upon installation.

3. With a mechanical tensioner, allowing the car to roll backwards while in gear, causing the engine to rotate backwards. This could happen while parking on a hill for instance. This is not an issue with the hydraulic de-tensioner or fixed-type (ZAT) tensioner.

>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>

If there’s one aspect of the 164 12v V-6 engines that strikes terror into the hearts of it’s owners, it’s the timing belt. Keeping in mind that since these 164 engines were designed in the 80s and the timing belts are of the early trapezoidal design. This means the teeth on the belt form a small trapazoid. More modern belt designs are of the “curvilinear” type which forms a sort of half circle. The trapezoidal types do not have the amount of grip that that the modern curvilinear types do. That said, trapezoidal belts are just fine under most circumstances, given sufficient “belt wrap.” Belt wrap is the how much of the belt grips the pulley which it drives. A trapezoidal belt with lots of “wrap” grips the pulley well and poses no special problem.

Later Alfa V-6 engines use a curvilinear belt. As an aside, early 12v engines can be retrofitted to use the curvilinear belts, but finding the various pulleys/pieces/parts is difficult and must be sourced from Europe.

Which brings us to back to the 164 12v Busso engine. The problem with the early Busso engine is that the belt wrap on the rear camshaft pulley can reasonably be described as “just barely adequate.”

Under good circumstances, given good maintenance, non-extreme conditions, and not allowing the engine to rotate backwards, it works fine. However, given problems and the right circumstances, there is a real possibility that the belt will skip/shear teeth and go out of valve timing. Given that the engine is an “interference” type engine, if the timing slips by more than 2 teeth, it’s almost a certainty that there will be a collision between some valves and the piston. The result of this is a very expensive repair and very often has led to the car being junked as non-economical to repair. And virtually all of this is unnecessary and preventable.

Causes of 12v Timing Belt Failures

The VAST majority of timing belt failures can be attributed to three causes:

1. Failure to adhere to Alfa recommended change intervals.

2. Failure of the temperature sensitive tensioner spring of the mechanical type tensioner. This can either be by simple material failure or by installation error with the installer inadvertently breaking it upon installation.

3. With a mechanical tensioner, allowing the car to roll backwards while in gear, causing the engine to rotate backwards. This could happen while parking on a hill for instance. This is not an issue with the hydraulic de-tensioner or fixed-type (ZAT) tensioner.